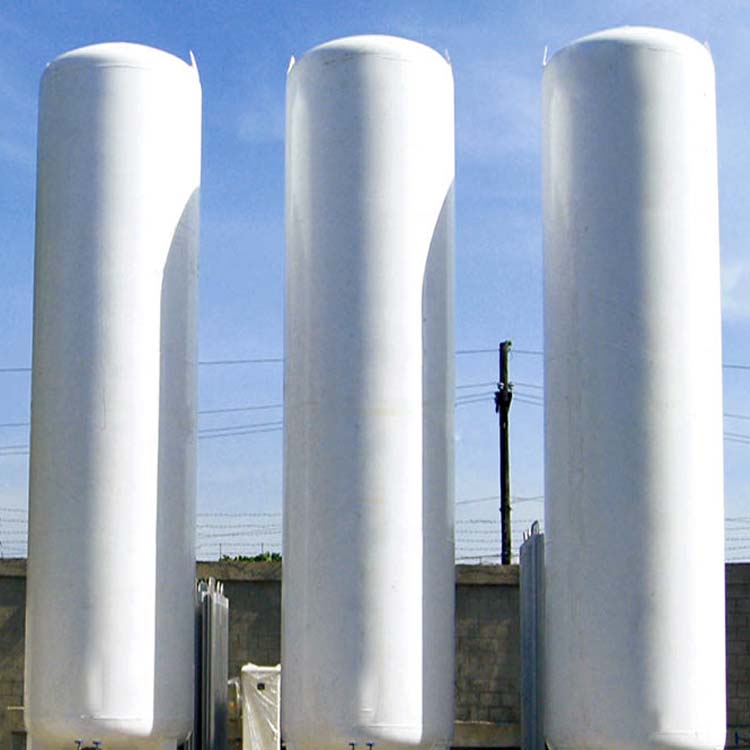

LCO2 tank carbon dioxide pant

Our LCO2 tank advantage:

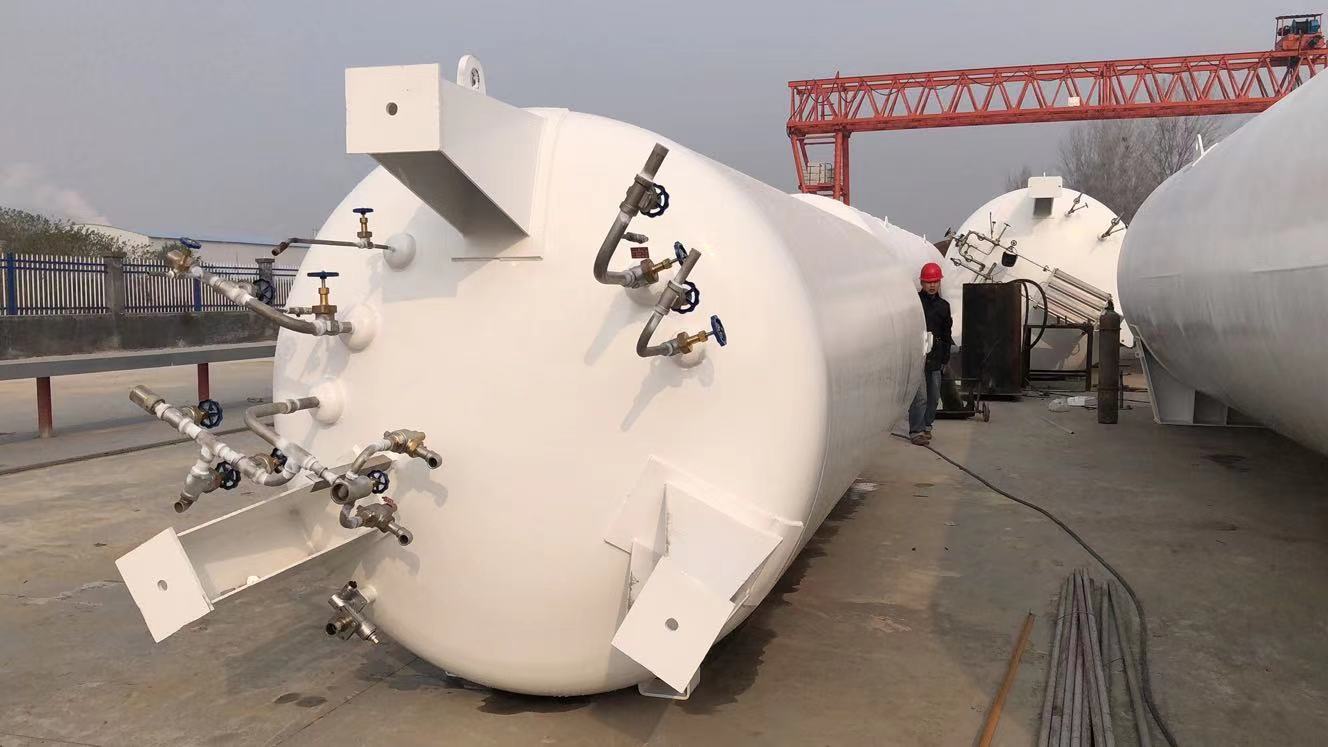

The blanking is carried out by CNC plasma cutting machine, and the geometric dimensions of the cylinder section are strictly packed.

Submerged arc welding is used for longitudinal and circumferential seam welding, the appearance is good, and the inner tank is 100% X-ray inspection.

The pipe is bent on a CNC pipe bending machine, which strictly guarantees the geometric size of the pipe.

The inner and outer surfaces of the carbon steel shell are sandblasted to remove rust, which ensures the adhesion of the paint, prolongs the corrosion resistance of the paint, improves the corrosion resistance of the stainless steel plate, and reduces the outgassing of the interlayer, which ensures the carbon dioxide storage tank. vacuum life.

Before the sand is loaded, the pearlescent sand is subjected to a unique dehydration pretreatment, and the interlayer is heated and replaced with nitrogen, which greatly reduces the gas source.

The sand filling adopts the process of negative pressure filling and positive pressure compaction, which ensures the uniformity of the interlayer pearlescent sand and the cooling effect of the interlayer.

Primer twice and topcoat twice to ensure the life of the paint