Operation procedure for filling liquid petroleum gas

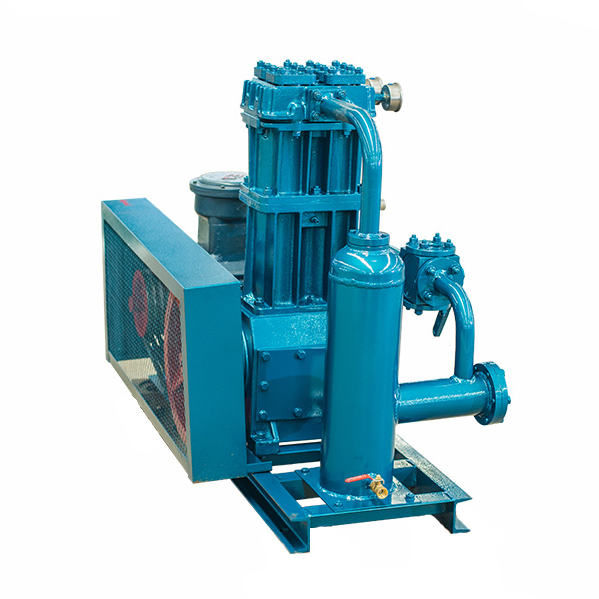

Operation procedure for filling liquid with LPG compressor

①Open the valve from the gas phase outlet of the liquid inlet storage tank to the inlet pipeline of the liquefied petroleum gas compressor, and open the liquefied petroleum gas compressor.

The valve of the oil and gas compressor outlet to the gas phase pipeline of the liquefied petroleum gas truck tanker.

②Open the valve from the liquid phase inlet of the liquid inlet storage tank to the liquid phase pipeline of the LPG truck tanker.

③Notify the operator to start the compressor, so that the liquefied petroleum gas in the tanker is input into the liquid storage tank.

④When the liquid level indication of the tank truck is close to zero, the liquid injection is completed, and the operator is notified to stop.

⑤Close the gas and liquid phase valves mentioned above in this operation.

⑥ Fill out the operation record form as required.

Matters needing attention

① It is strictly forbidden to overfill the liquid. When the liquid level gauge shows no change, stop the liquid filling operation and eliminate the fault.

②The filling pressure should be less than or equal to 1.5MPa. The liquid temperature should be ≤50°C, when the liquid temperature reaches 40°C, the cooling water should be sprayed

temperature.

③ It is not allowed to fill two storage tanks at the same time.