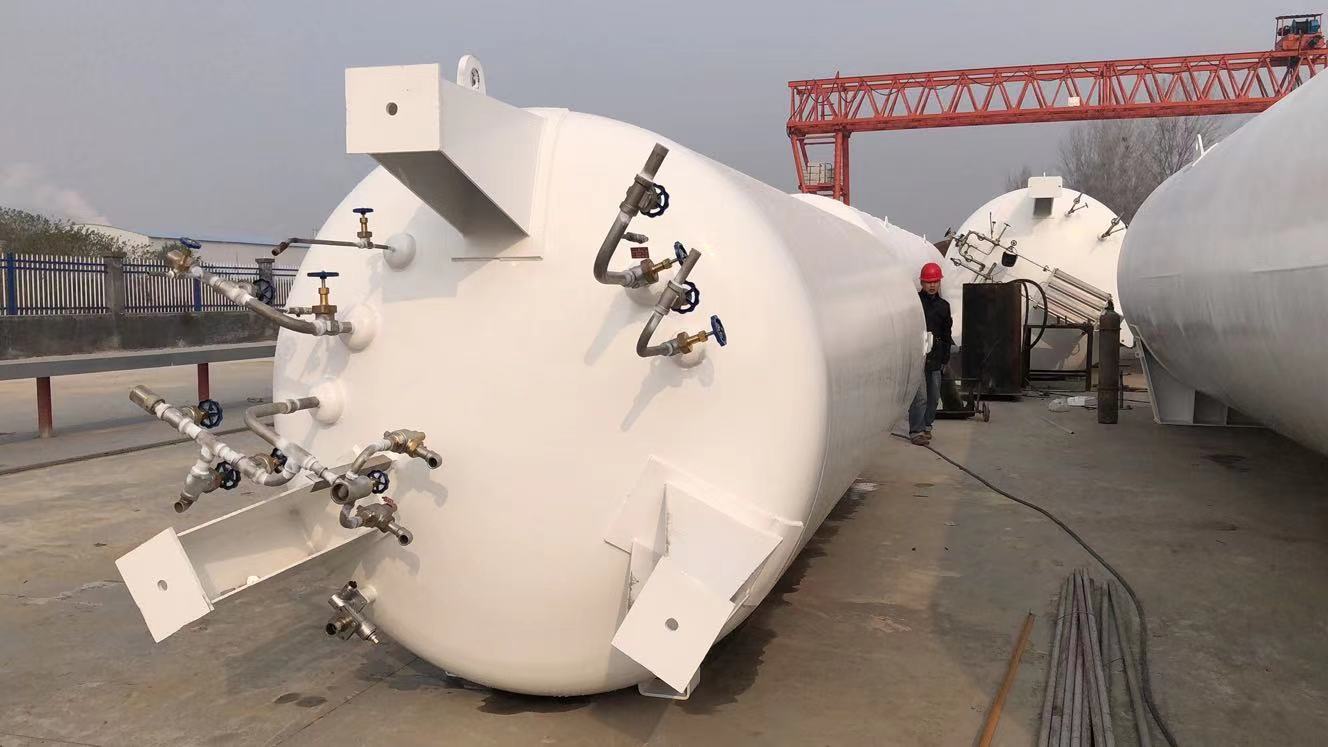

30 feet cryogenic tank

Specific process of liquid oxygen storage tank

Specific process of liquid oxygen storage tank

1. Prepare enough before use. Sufficient preparation means checking the pressure display value of the liquid oxygen storage tank and the display value of the water level gauge. Check storage tank parts for damage. Proceed to the next step after confirming that there is no abnormality in the parts and that the displayed value is normal.

2. Connect the relevant pipelines. Close all valves then open the drain valve. Leveling valves and flow valves, etc.

3. Open the drain valve and drain valve to clear the piping. Then turn off the power after cleaning. Then open the upper intake and discharge valves of the supercharger.

4. Wait for the pressure to stabilize and open the large liquid inlet valve to speed up the filling. Then, close the level gauge, equalize the valve, and check that there is 300 to 500 mm of liquid in the level gauge before closing.

5. When the liquid in the tank is close to the loading capacity, the overflow valve can be opened at this time. The overflow valve closes the tanker’s valve when it spouts liquid oxygen.

6. Open the relief valve, relieve pressure and close it.

7. The first step is to record and complete all work procedures.