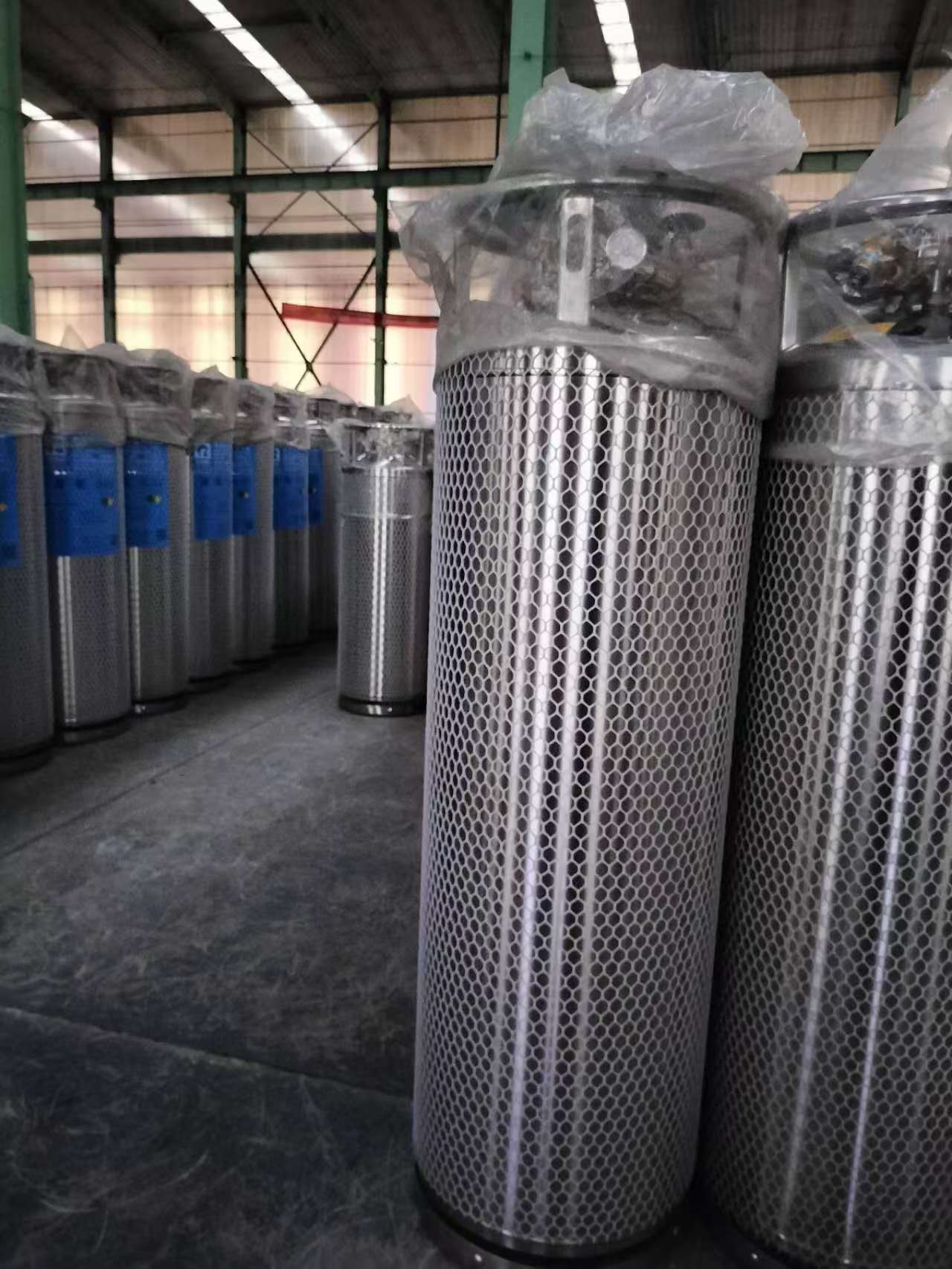

Dewar bottle operation precautions

1. When engaging in any work with cryogenic liquids, you must wear protective equipment to prevent frostbite.

2. During the operation of liquid oxygen, the valve should be opened and closed slowly. If it is opened and closed suddenly, the oxygen flow will ignite any contamination in the system.

3. Except for liquid oxygen, all liquid vapors can cause suffocation.

4. The filling volume cannot exceed: 192kg of liquid oxygen, 136kg of liquid nitrogen, and 230kg of liquid argon.

5. When using liquid, it is recommended to reduce the pressure inside the bottle as much as possible.

6. The cylinder must be kept upright during operation, and tipping over should be avoided. Never roll the cylinder horizontally.

7. Open flames are strictly prohibited within 5m around the storage, vaporization, filling and use of liquid oxygen. All fire sources must be eliminated, and there should be obvious no fire signs.

8. There are no openings leading to low places (such as basements, pits, underground wells, ditches) within at least 5m around the storage, vaporization, filling and use of liquid oxygen; there must be a liquid-blocking weir at the entrance of the trench. .

9. When filling or handling liquid oxygen, operators are not allowed to wear work clothes and personal protective equipment contaminated by grease. All clothes and protective equipment contaminated by grease must be replaced.