Liquid oxygen filling stations

Liquid oxygen filling stations require a series of equipment to ensure safe and efficient filling of liquid oxygen into cylinders. Here are the main pieces of equipment you may need at a liquid oxygen refueling station:

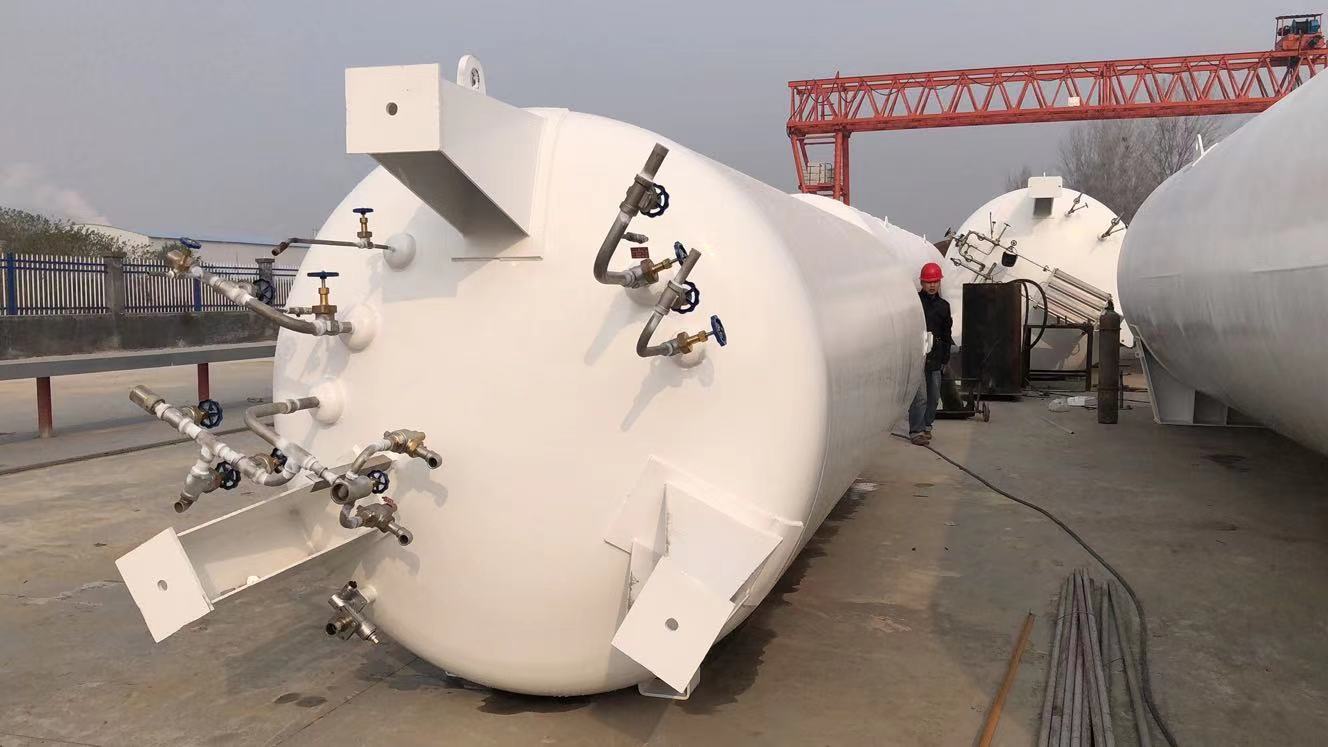

Liquid Oxygen Storage Tank: A container, usually a high-pressure vessel, used to store large amounts of liquid oxygen, capable of keeping the liquid oxygen in a liquid state at extremely low temperatures.

Liquid oxygen filling equipment: includes pumps, piping systems and control systems used to transport liquid oxygen from storage tanks to cylinders to be filled. Ensure liquid oxygen is delivered to the cylinder at the proper pressure and flow rate.

Cylinder Filling System: Equipment used to support and safely fill liquid oxygen into cylinders. This may include filling racks, fixtures, etc.

Liquid oxygen mass analyzer: used to monitor the quality of filled liquid oxygen to ensure that it meets the specified purity standards.

Cylinder inspection system: Used to ensure that the cylinders to be filled meet safety and quality standards during the filling process. This may include pressure sensors, temperature sensors, etc.

Safety system: Including fire detectors, emergency stop systems, gas leak detectors, etc. to ensure the safety of gas filling stations.

Control System: A computer system used to monitor and control the liquid oxygen filling process. This includes automated control systems to ensure the filling process is stable, safe and compliant.

Gas recovery system: Recycle and re-compress gas to reduce gas waste and improve efficiency.

Liquid oxygen tank and equipment insulation systems: Used to reduce liquid oxygen evaporation and maintain equipment performance in low-temperature environments.

Supporting equipment: including liquid oxygen cleaning equipment, drying equipment, filling equipment, etc. to ensure that the gas filling station can be fully operated and maintained.

When designing and operating a liquid oxygen filling station, relevant regulations and standards must be followed to ensure the safety and quality of the equipment. Operations personnel also need to receive professional training to properly operate and maintain liquid oxygen filling station equipment.