Liquid argon cryogenic pump types

As a key equipment specially used for transporting cryogenic liquid argon, liquid argon cryogenic pump plays an indispensable role in many fields.

As a key equipment specially used for transporting cryogenic liquid argon, liquid argon cryogenic pump plays an indispensable role in many fields.

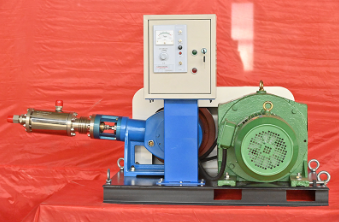

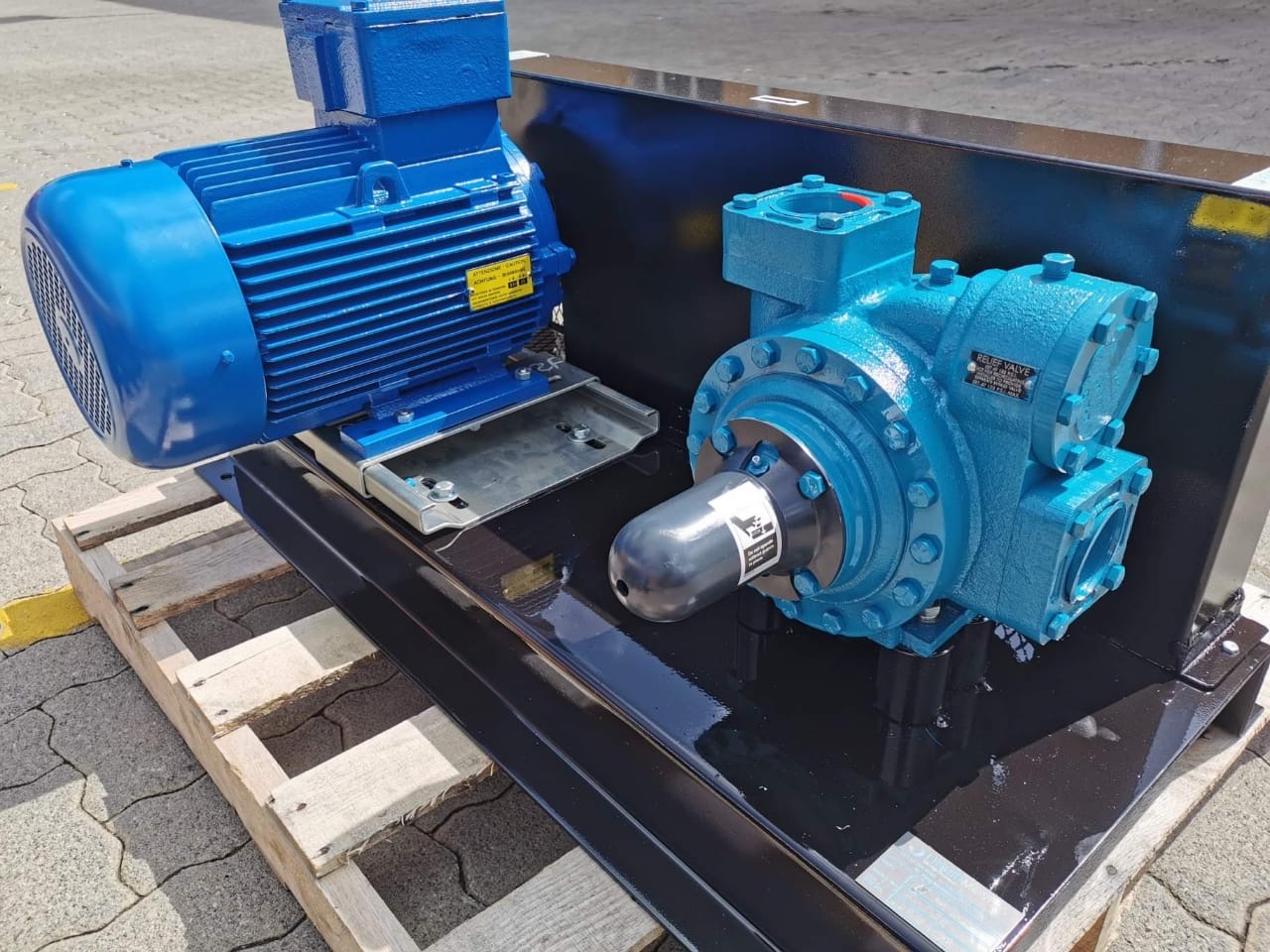

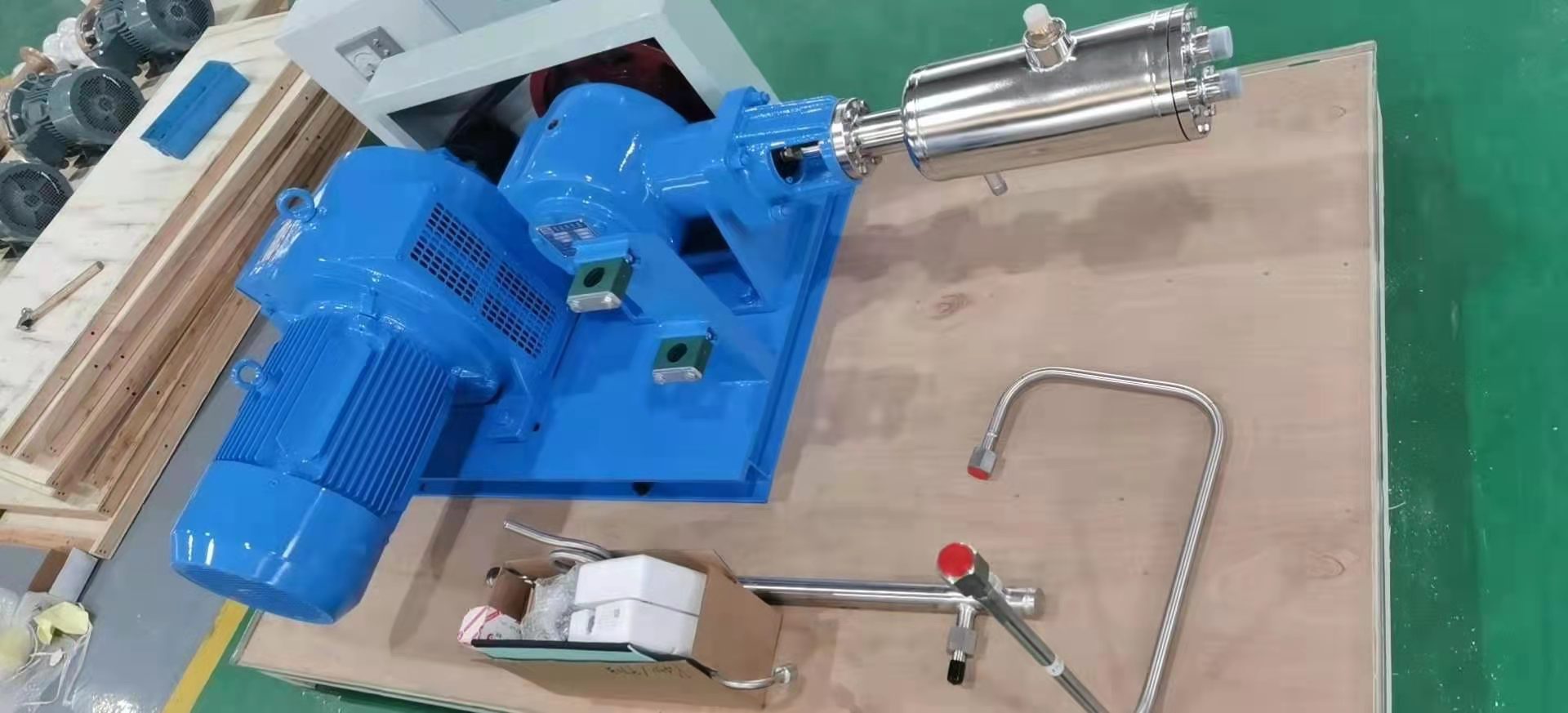

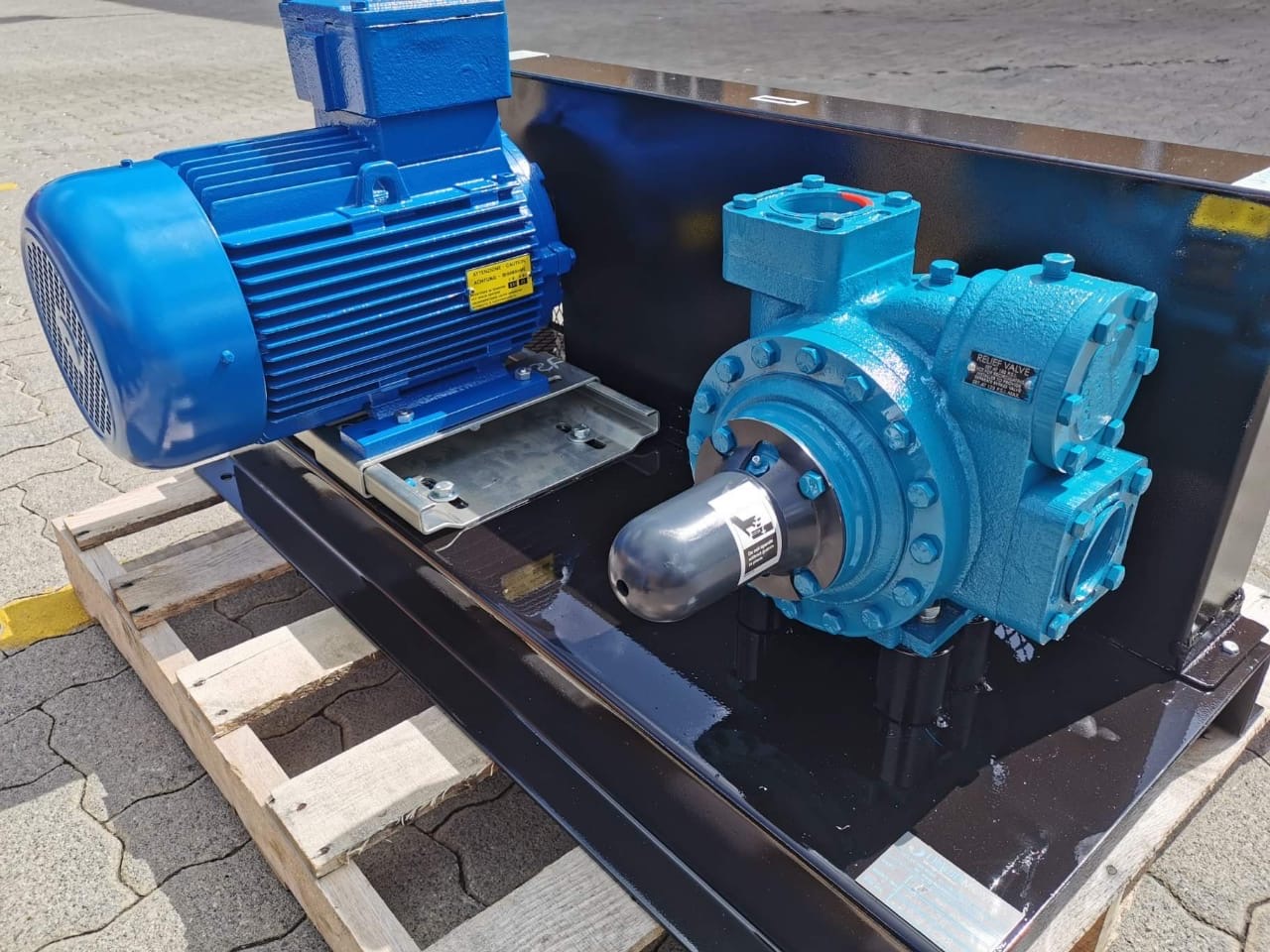

From the working principle, it mainly has two types: centrifugal and reciprocating. The centrifugal liquid argon cryogenic pump relies on the rotating impeller to work on the liquid and transfer the mechanical energy of the prime mover to the liquid. When the pump is full of liquid and working, due to the high-speed rotation of the impeller, the liquid generates centrifugal force under the action of the impeller, driving the liquid from the impeller inlet to the outlet. In the process of flowing, the pressure energy and velocity energy increase, and then the velocity energy is further converted into pressure energy in the expansion chamber and then output. The reciprocating liquid argon cryogenic pump is similar to the working principle of the reciprocating compressor and is a volumetric compression machine. The piston (plunger) reciprocates in the working chamber of the liquid cylinder, causing the volume of the working chamber to change periodically to realize the whole process of suction, compression and discharge. When the piston moves to the right, the volume of the pump cylinder increases, the pressure decreases, the suction valve opens, and the liquid flows into the pump cylinder; when the piston moves to the left, the volume of the pump cylinder decreases, the pressure increases, the discharge valve opens, and the high-pressure liquid is discharged.