Maintenance of CO2 Cryogenic Pump

When a CO2 cryogenic pump fails, the machine should be shut down and the power supply should be cut off first to ensure a safe maintenance environment.

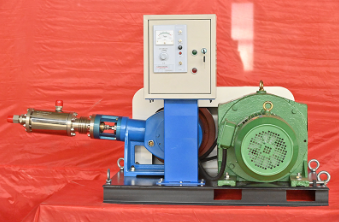

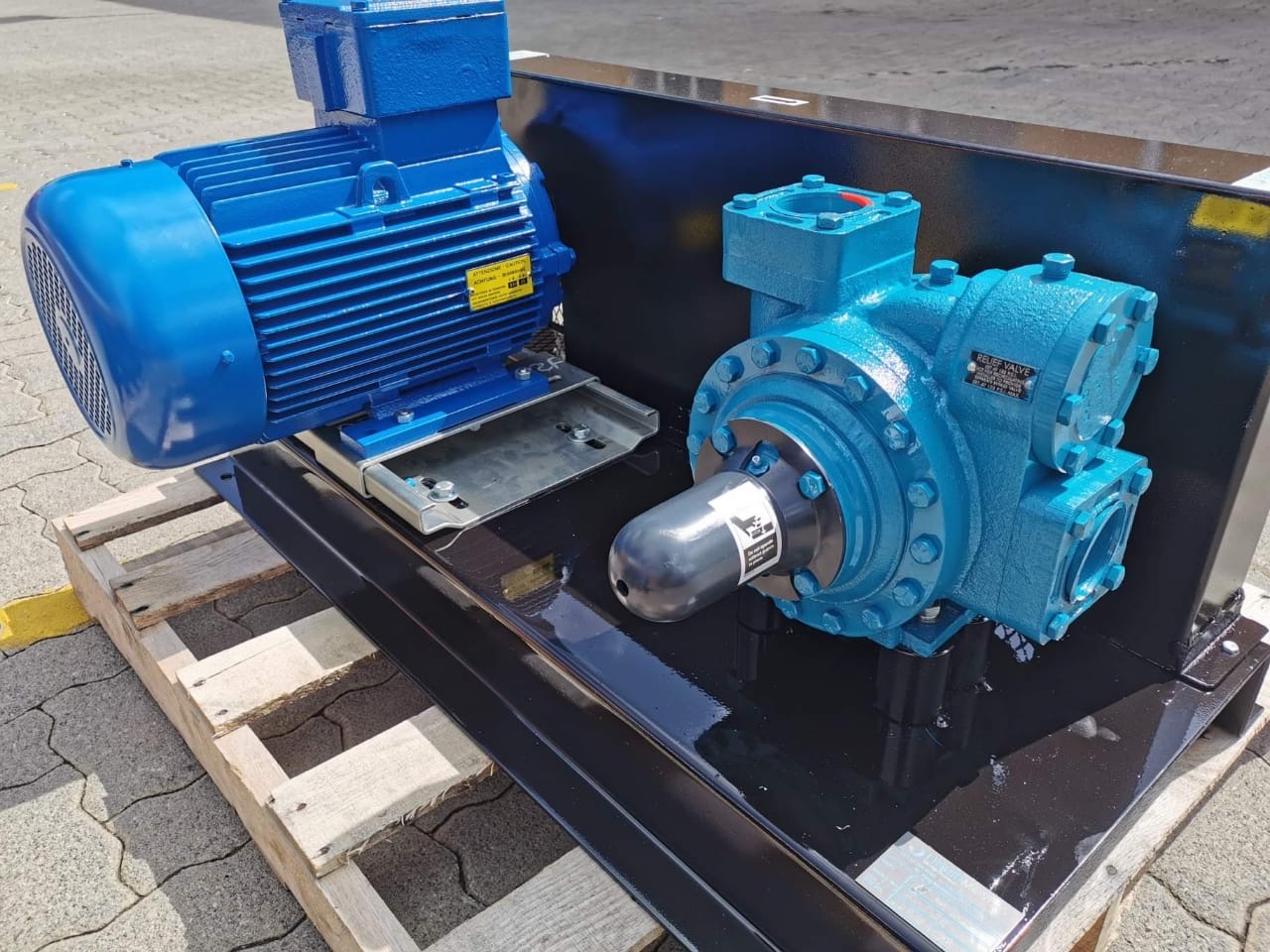

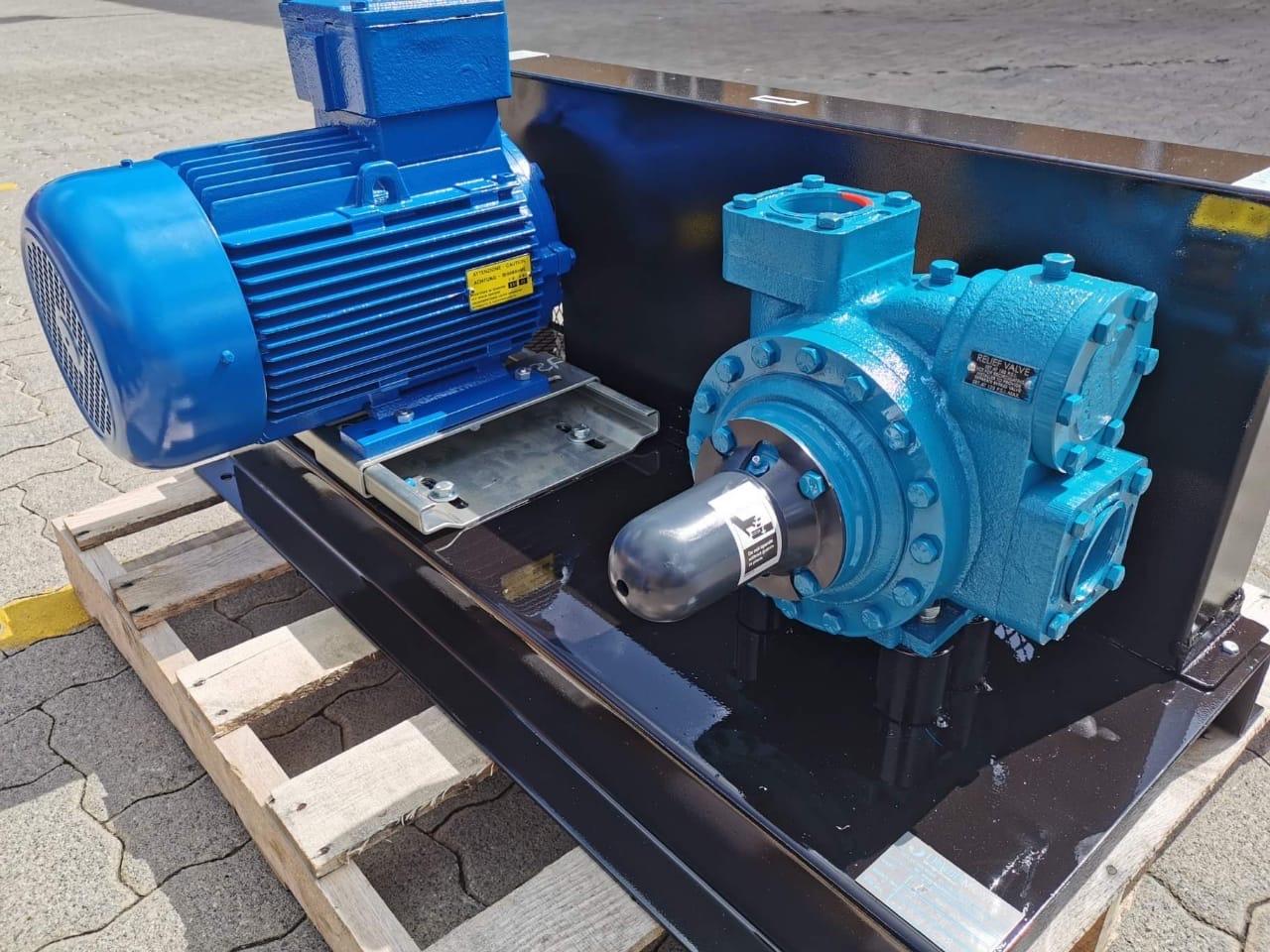

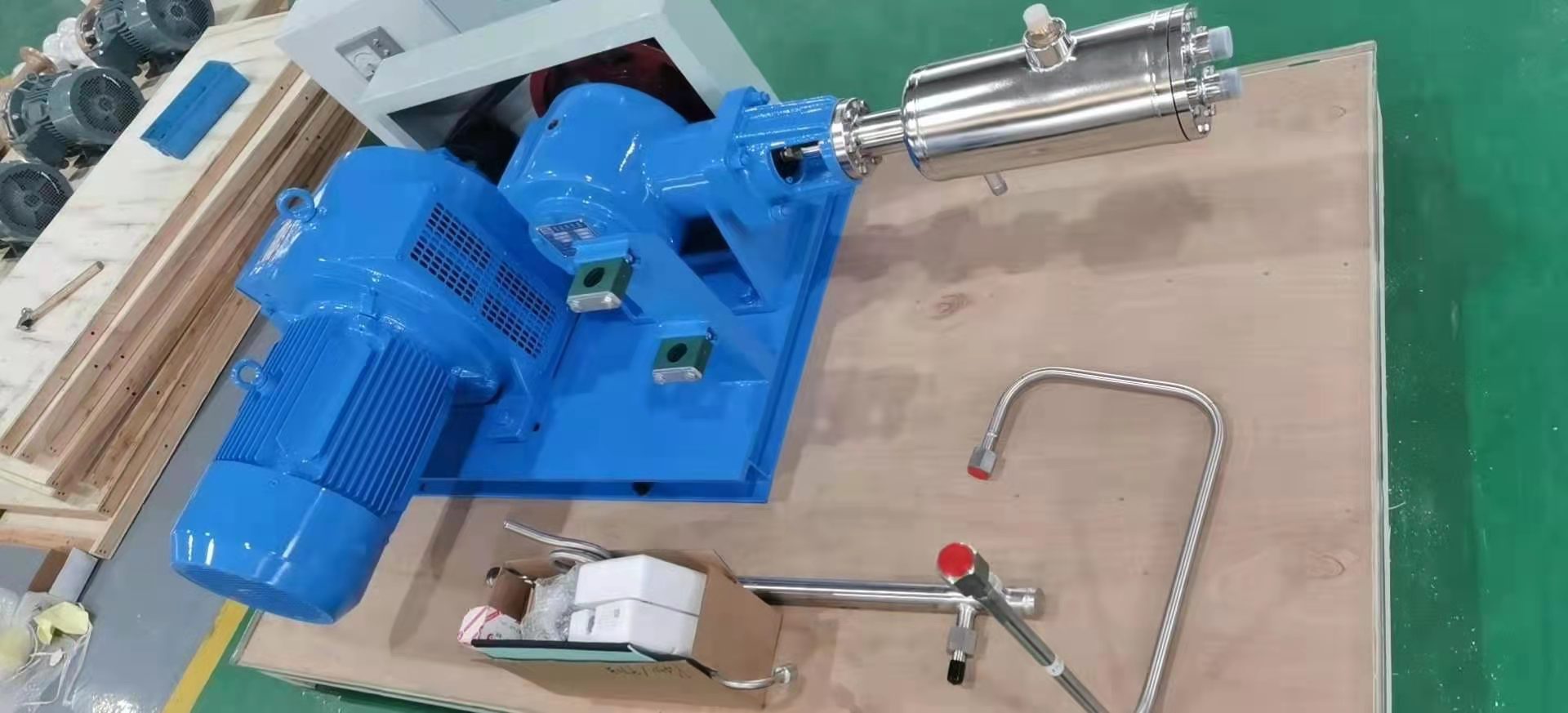

When a CO2 cryogenic pump fails, the machine should be shut down and the power supply should be cut off first to ensure a safe maintenance environment. Check the appearance of the pump for damage and whether the connection parts are loose or leaking. For mechanical failures, there may be problems such as bearing wear, impeller blockage or pump shaft deformation. Bearings need to be replaced, impellers cleaned or pump shafts corrected. If there is a leak at the seal, check whether the seal is aged or damaged. If there is a problem, replace the seal and adjust the clamping device. For electrical failures, check whether the cables and terminals are loose or damaged, and measure the insulation resistance and operating current of the motor to see if they are normal. After maintenance, conduct a trial run to ensure that the pump can work normally and all parameters meet the requirements to ensure its stable operation in industrial production, energy fields, scientific research and other applications.