The equipment required to supply a boiler

The equipment required to supply a boiler for a liquefied petroleum gas (LPG) system typically includes the following components:

LPG Storage Tank: An LPG storage tank is a container specially designed to store liquefied petroleum gas. The size of the storage tank depends on the user’s needs and the amount of LPG used. Storage tanks are usually pressure vessels and need to comply with relevant safety standards and regulations.

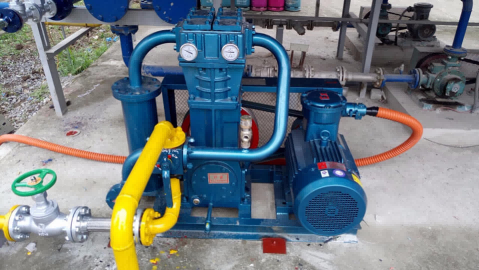

LPG Delivery System: This system is used to deliver LPG from storage tanks to boilers. This may include pipes, valves, connections and other conveying equipment. Pipe systems need to be well designed and installed to ensure that gas can be delivered safely and efficiently.

Boiler: A boiler is a device that burns liquefied petroleum gas to produce heat energy. Boiler systems typically include combustion chambers, burners, heat exchangers, control systems and safety equipment. The boiler needs to be matched with the LPG system to ensure smooth combustion and efficient energy utilization.

Burner: A burner is a device used to introduce LPG into the combustion chamber and ignite it. The design of the burner needs to take into account the characteristics of LPG to ensure that combustion is safe and effective.

Control System: The control system is used to monitor and control the operation of the boiler. This includes monitoring and regulating parameters such as temperature, pressure, and gas flow. A good control system helps improve energy efficiency and ensures the safe operation of equipment.

Safety equipment: Safety equipment is a key part to ensure the safe operation of the LPG system, including valves, pressure relief devices, leak detectors, etc. These devices help prevent potentially dangerous situations such as overpressure, leaks, etc.

Pipe fittings and valves: Pipe connections and valves are used to control and regulate the flow of LPG. They need to be carefully designed and regularly inspected to ensure system reliability and safety.

When designing and installing an LPG heating system, it is recommended to work with a professional engineer or contractor to ensure the system complies with local and national regulations and operates safely and efficiently. In addition, regular maintenance and inspections are also very important to ensure the normal operation and safety of the system.